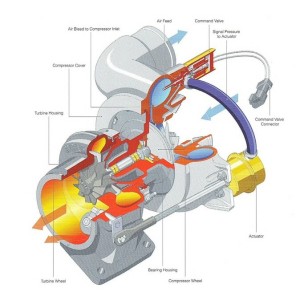

Turbocharger is made up of three main components, the proper design and execution of guarantees to ensure the assumed level of boost and mechanical efficiency. The first element is the housingmiddle, which is a ballbearing  shaft connecting the turbine wheel compressor wheel. The second element is a gas turbine (which is here a kind of engine), which drives the compressor wheel via shaft. And finally, the third part is the compressor (compressor) centrifugal type.

shaft connecting the turbine wheel compressor wheel. The second element is a gas turbine (which is here a kind of engine), which drives the compressor wheel via shaft. And finally, the third part is the compressor (compressor) centrifugal type.

In addition, the turbo engines operating in a wide speed range or in the turbochargers on small moments of inertia of rotating systems, which give the effect of boost at low engine speeds, there is a regulating device maximum charge pressure (implemented through the vent to exhaust by-pass or a variable geometry turbine housing) .

Middle housing connected to the housing of the compressor and the turbine comprises a rigid whole.

The compressor wheel and the turbine wheel are mounted on a common shaft which is supported, in most embodiments, the use of hydrodynamic bearings and the transverse double-acting thrust bearing. It must be added that the turbine wheel is integral with the shaft whole, while the compressor wheel is mounted on the second end of the shaft with the bearing housing longitudinal and locked with a nut. The turbine wheel via shaft drive transfers given by the exhaust gases of the compressor wheel.